Silica Tape A heat resistant substance found the use across communicating with plenty of businesses require high-temperature thermal protection and insulation that is excellent. It possesses distinctive properties, which makes it perfect for a wide variety of applications from aerospace engineering all the way down electrical insulation. That is the world where successful production of professional silica tape occurs, a balancing act between intense customization and precision required to answer questions in dozens of industries but doing so without sacrificing quality or its place on this earth. In this journey, we give you a glimpse behind the curtain of silica tape manufacturing to provide an extensive step-by-step guide for choosing the best supplier, understanding customization aspects and tips on quality control and eco-friendly practices.

Looking to the Scenes of Our Silica Tape Production Process

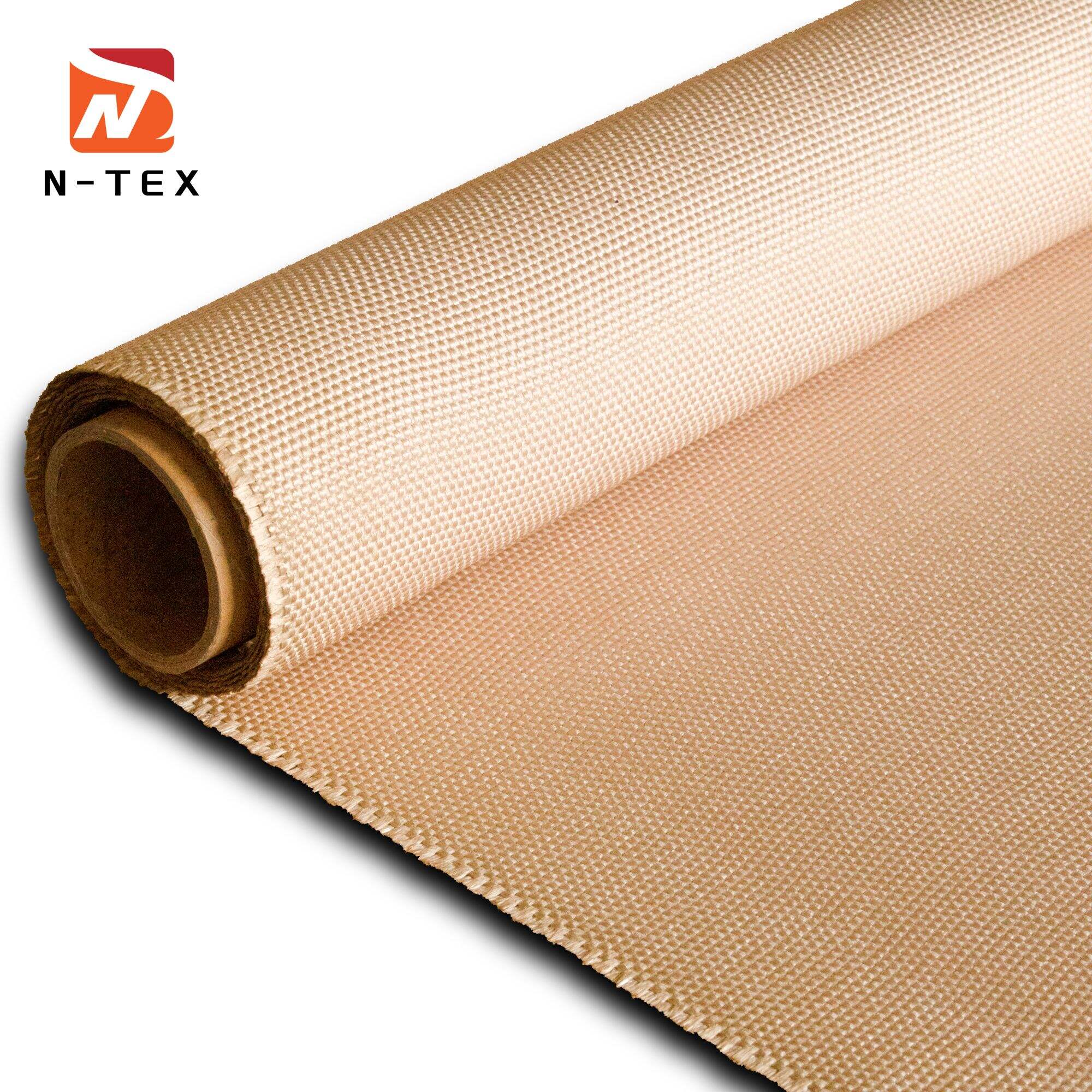

Silicatape is as much a matter of science and artistic endeavor before it's crafted to its high-end state. First, you start out with sourcing pristine silica fibers (flexible fabric is woven or knitted for strength). This fabric has better strength series operations strengthening its heat resistance and other mechanical properties. One of the most significant measures to take is proprietary silicone (or other high-temperature resistant coatings) formulations that are used as an overcoat for the tape, thereby bettering its performance in harsh working conditions. Beginning with raw material inspection and ending at product testing, these steps keep intact the consistency of products manufactured as well as adhere to international standards. This kind of technology with judicious craftsmanship allows the silica tapes produced using such a mechanism to be used as a security for some delicate industries, where precision is no. 1 word.

How to Choose Silica Tape Supplier for Your Business

The selection of a supplier for silica tapes is also strategic and makes all the difference in production processes, bringing an increase to your product quality as well. If a reputable supplier of quality silica tape products for multiple purposes has operated in an industrial and commercial space, it must be well aware. All of your suppliers with ISO certifications -- You have committed to their quality management system, come-hell-or-high-water. Consideration Of The Research And Development Capabilities You also want to examine how much resources are invested into research and development, because the faster paced your supplier is at innovation the more efficiently they can relay their products remain current Use of customer service will be another big extenuating factor between you as a client - fast lead times and flexible pricing just further smooth out that back-and-forth.transaction. Also, remember that suppliers who are open with their manufacturing procedures to prove the do not lie can be trusted.

Customizing Woven Silica Tapes for Market Trends

The methods for applying silica tape, cannot be universally applied. From the thickness, width adhesive backing to temperature resistance level - these are just a couple of tons of parameters have to configure it for different industry requirements. Together with the customer, our team decides as to what kind of properties that are required - ranging from abrasion resistance all through flexibility or even dielectric strength and we engineer in such characteristics on tape level. The aerospace market, for instance, might need very thin tapes of high strength that are used to insulate wiring while the automotive sector may be in search of specialized fire-resistant tape to line engine compartments. We leverage advanced solutions and innovative material science to create precision-designed specialty products made from everyday silica tape that enhance the quality and safety of end-products.

Taking the Lead in Silica Tape Production

By definition aims to be a pursuit as it is embedded across all of our operations, not only the goals. We have a culture of constant developments so each batch is much better than previous one. We keep our staff in training permanently so that they are always on top of the latest practices and we also benefit from not having people being paranoid about their jobs due to lack of work. We, therefore,demand that all finished parts not only meet the customer specifications but also our high standards and from processing control inspections to output tests this is achieved by extreme caution of our quality department Our R&D team are eager ways for possible new special materials as well technology in improving silica tape properties. That dedication to quality means that the products go above and beyond, allowing our customers extra peace of mind.

Sustainability of Silica Tape

Aware of the ever growing need for sustainable manufacturing we have introduced a green process with our silica tape production. We strive to minimize our CO2 emissions by choosing only sustainable materials, using energy-efficient production methods and selecting responsible suppliers. The measures start with recycling of production scraps and the efficient material usage, first, in order to reduce waste generation In addition, we have water and chemical management systems to avoid further contamination of the environment. We are partnering with green marketing trends to create a demand for environment-friendly products and at the same time implementing them, i.e., we will package our food in biodegradable or recyclable material as part of this sustainability promise. Whilst this full manufacturing assault complements as much for our green credentials than it does for making market leading Silica Tapes.

In the end it shows how professional silica tape manufacturing really is more than just production, but knowing what customers need and want to make this materials work on a higher level of technology; still responsible too for its ecosystem. With our best in class method of manufacturing for accuracy, bespoke respecifications and world-leading quality & sustainability we want to be more than just a supplier - but your innovation partner helping you deliver maximum output.