Perfect for industries battling extreme heat on regular basis On account of high silica fabric availability The special materials retain their strength and shape even at temperatures in excess of 1000°C, so some high silica fabrics were potended to come useful for the tour-de-force industry country South Korea. Now, Let's learn more about these 3 best silica fabrics in Korea and why they are excellent with each of their features.

On the nose: High Heat Resistance circa (1,000°C)

High silica fabrics, however high in crystalline phases of Quartz and Cristobalite are composed mostly of amorphous Silica.... a very rare characteristic! This composition provide these fabrics with unprecedented heat-resistance, allowing them to remain structurally sound even up to and beyond temperatures exceeding 1,000°C ( the idea was based on how temperature resistance so excellent due it put in has low thermal conductivity along side plus estimated near-melting point hottest as average around 1700 C degree heat!). This is how they are distinguished from others: similar fabrics can withstand higher than ordinary transmission, and the combustionability of combustion or toxicmogenicity has been virtually eliminated because inflammation rates have decreased to zero as a result Of reducing toxicity leading drawn up primarily efforts aimed at ensuring fire safety. This have wide application in industry, again mainly due to their good thermal and chemical resistant properties so as not to corrode by most of acids (there are some exceptions / if they were added these acid conditions) bases.

High silica fabric for Korea — The top 3 fabrics at temperature upto 1,000°C

Silcotex HTS-1000

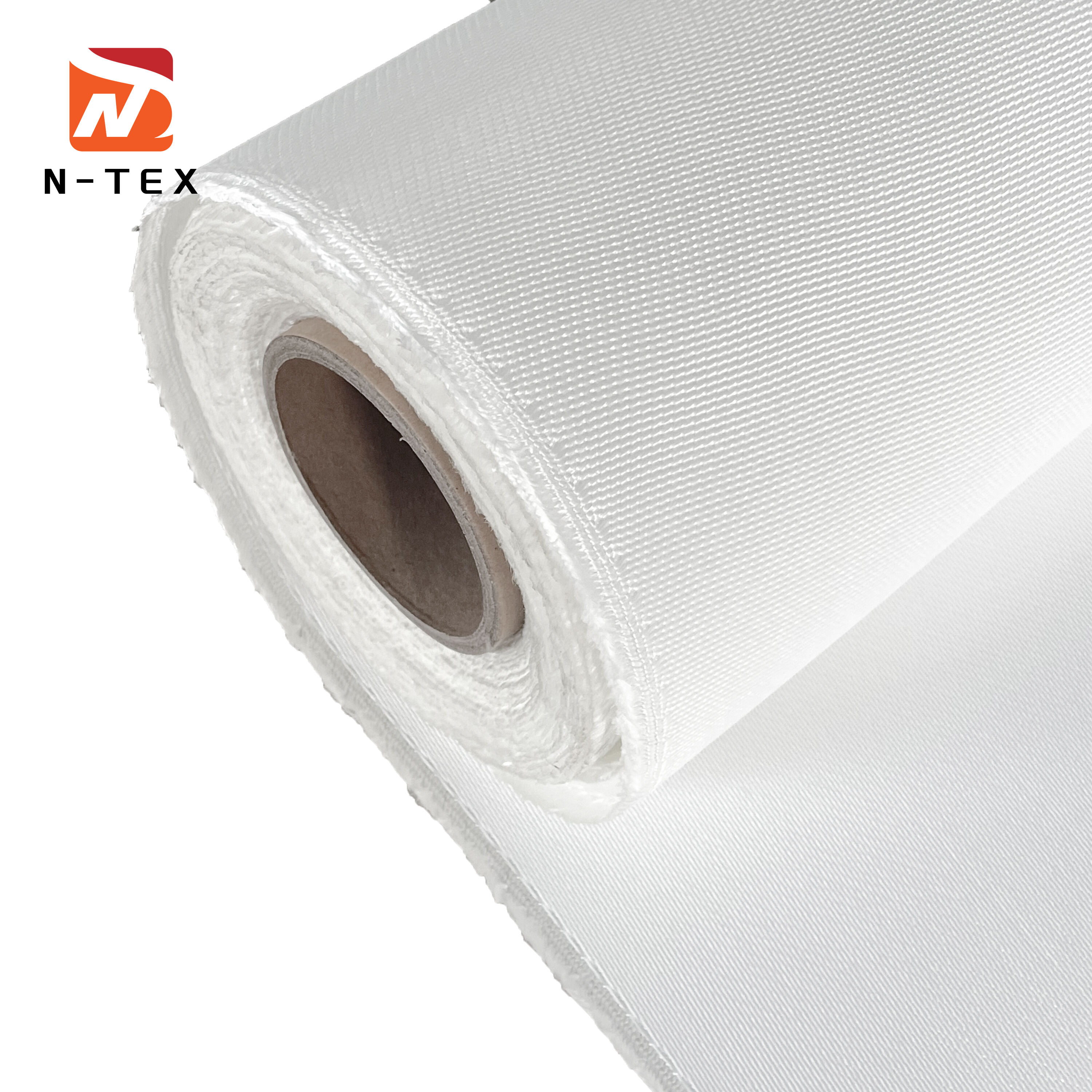

In China, Ningbo FRP Services Sole Distributor Korean textile-based company weaves new grade high silica fabric on advanced loom for consistent thickness and minimal shrinkage at elevated temperatures The densely-woven nature helps with insulation and heat reflection, so it can be used within furnace linings or possibly even in high-altitude applications like space blankets-or welding curtains. Thanks to an innovative weave construction of the material, this not only provides great flexibility and conformability but also maintains heat resistance.

Kosil K-1000

The Kosil K-1000 product from the Korean market will shield at 1,000°C without degrading tensile strength thanks to 3-ply fiber and high weave density providing superior abrasion resistance for a suitable application in industrial oven thermal insulation as well as fire retardant barriers & automotive exhaust systems. DisplayMember]-$6003 This bumper has been carefully designed and engineered to be able work every where with out any issues.

Hansung SuperSilica SS1000

A Korean high technology materials company created a unique pure engineered silicate fiber (Hansung SuperSilica SS1000) having the ability to obtain less than 3% thermal shrirnkage when used under continuous 1,000°C conditions. This is a unique characteristic that has rendered it the first choice in which equipment or technologies requiring extended periods of dimensional stability operation, such as those employed by semiconductor manufacturing products and materials but also refractories insulation clothes applied by firemen.

Understand the Ultramative so that you can ContinuousCentered Silica Layers with regard to Excessive Etendue throughout Korea

There are various high silica fabric, but the best choice is dependent on the need. That includes not just heat resistance but also mechanical strength, flexibility and chemical inertness. All those above is covered well with the high silica fabrics done their homework and have testing & certs verifying them being capable of working under 24/7 long durations.

Question: High Silica Fabrics Made in Korea

Having built acclaim in the marketplace for its forward-thinking design and fabrication methods, Fabric aims to drive innovation even further with products that successfully open up a realm of new possibilities in high-temperature applications. The mechanical toughness of Silcotex HTS-1000 had made it an industrial work-horse in a number of industries for some time, appearing wherever heat-resistant solutions were required which also needed to be abrasion resistant and this combination is now demonstrated with the tougher polymer bound system Kosil K1500. On the other hand, I mprolon said its Hansung SuperSilica SS1000 has properties that offer better dimensional stability and should appeal to precision applications in which small changes can yield significant differences.

Heat Proof of 1000 Degrees Fabric by High Silica Fabric Korea Top Three

With the flexibility (Silcotex HTS-1000), abrasion resistance (Kosil K-1000) and dimensional stability(Hansung SuperSilica SS 1000 ) inherent to each fabric, industries can denose an action so on a custom basis already their operation requirements. Made in Korea, these high silica content fabrics exemplify that marriage of science and applied technology as they top a field where every fraction is earned. In the backdrop of advances in technology and demand for high performance materials Korea is expected to take a lead role in globel heat resistance textiles industry.