High silica fabric. Ever heard of it? As it is made of silica, a mineral in the form of cloth. Silica is common in nature, being found most commonly in quartz. This mineral is often employed in fabricating glass since it possesses great toughness and can endure extreme temperatures without breaking or melting.

High silica material is used by producing strands (usually tiny and thin threads) of silica. These threads are incredibly strong and can withstand temperatures of up to 1,000 degrees Celsius! And most ovens can only get hot, but that is nearly as 1/3 of the temperature. Furthermore, high silica fabric is light in weight and can be readily moved around to use wherever needed.

It is quite useful in many industries especially because of high silica fabric can withstand these extremely temperatures. In aerospace, for instance, this material is used to produce heat shields. These heat shields shield craft and astronauts from the intense temperatures of launch and re-entry into Earth's atmosphere, respectively. The other major application of high silica fabric is as heat shield in under the hood applications on cars and trucks to prevent engine over heating. This prevents any kind of engine damage and enhances the performance of a vehicle.

High silica fabric has many properties which make it an important material in different fields. First, it is extremely robust and therefore heat resistant and durable. It is this strength that makes it ideal for the more demanding works which other substances would breakdown, or be unable to handle. Second, the material itself was lighter and easier to work with — which from a manufacturer perspective should suit them as well. The third property of high silica cloth is that it has flexibility; such type of fabric can be moulded into different dimensions and forms depending on the application. And finally, it is highly cost effective resulting in its applicability for multiple industries without taking a toll on the pocket.

The high silica fabric is being evolving, it has added different additional property such as strength and usage area in other field of uses that increase its use everyday. One such application of the 3D Printing is to make some special bandages for burn users in Medical. This helps protect and heal the skin. High silica fabric is also used in construction to reinforce concrete structures, making buildings and bridges stronger and longer lasting. Designers have used high silica fabric to design even within the fashion world, creating outfits that are great looking while also providing a buffer against heat and allowing them not only look their best but do so without concern of damage.

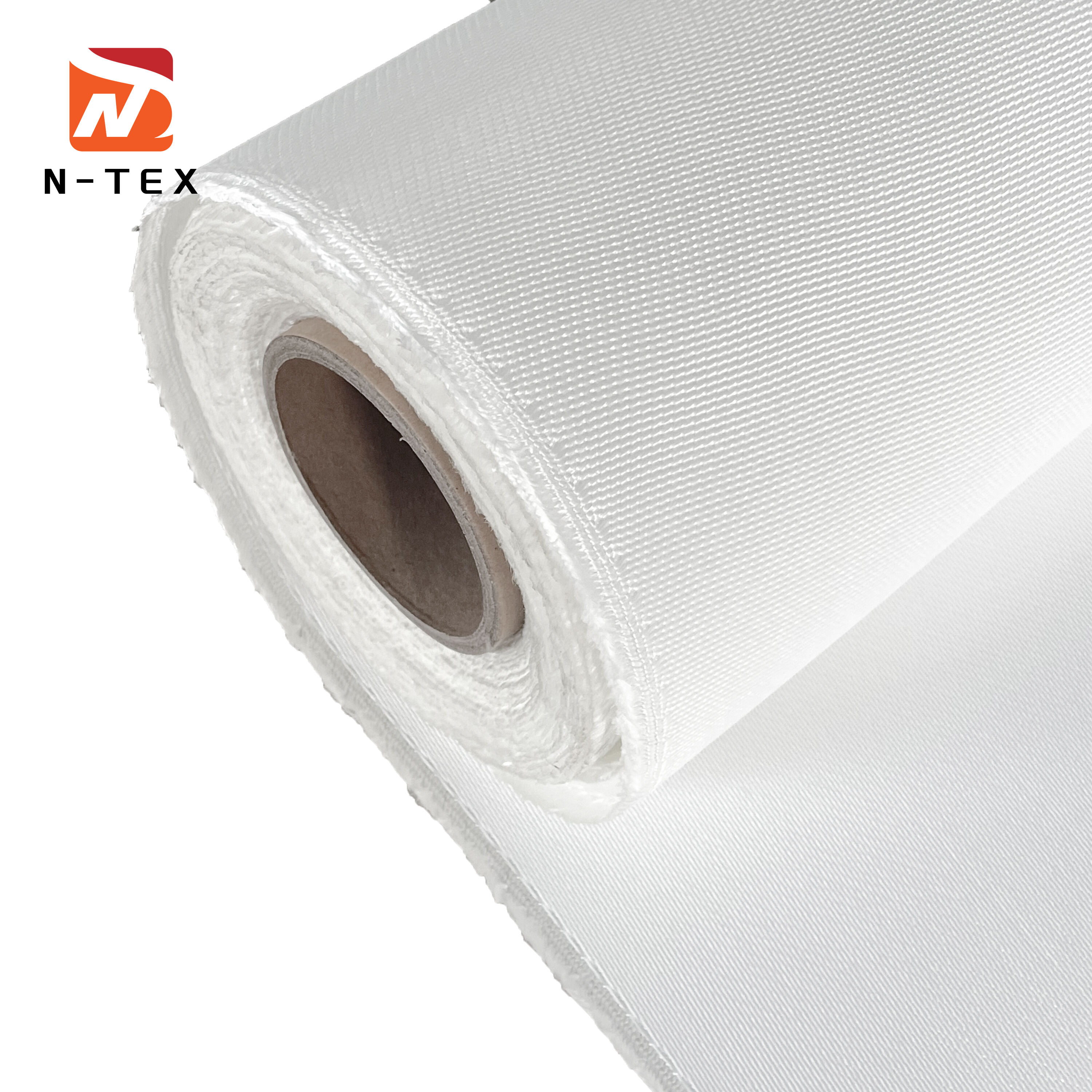

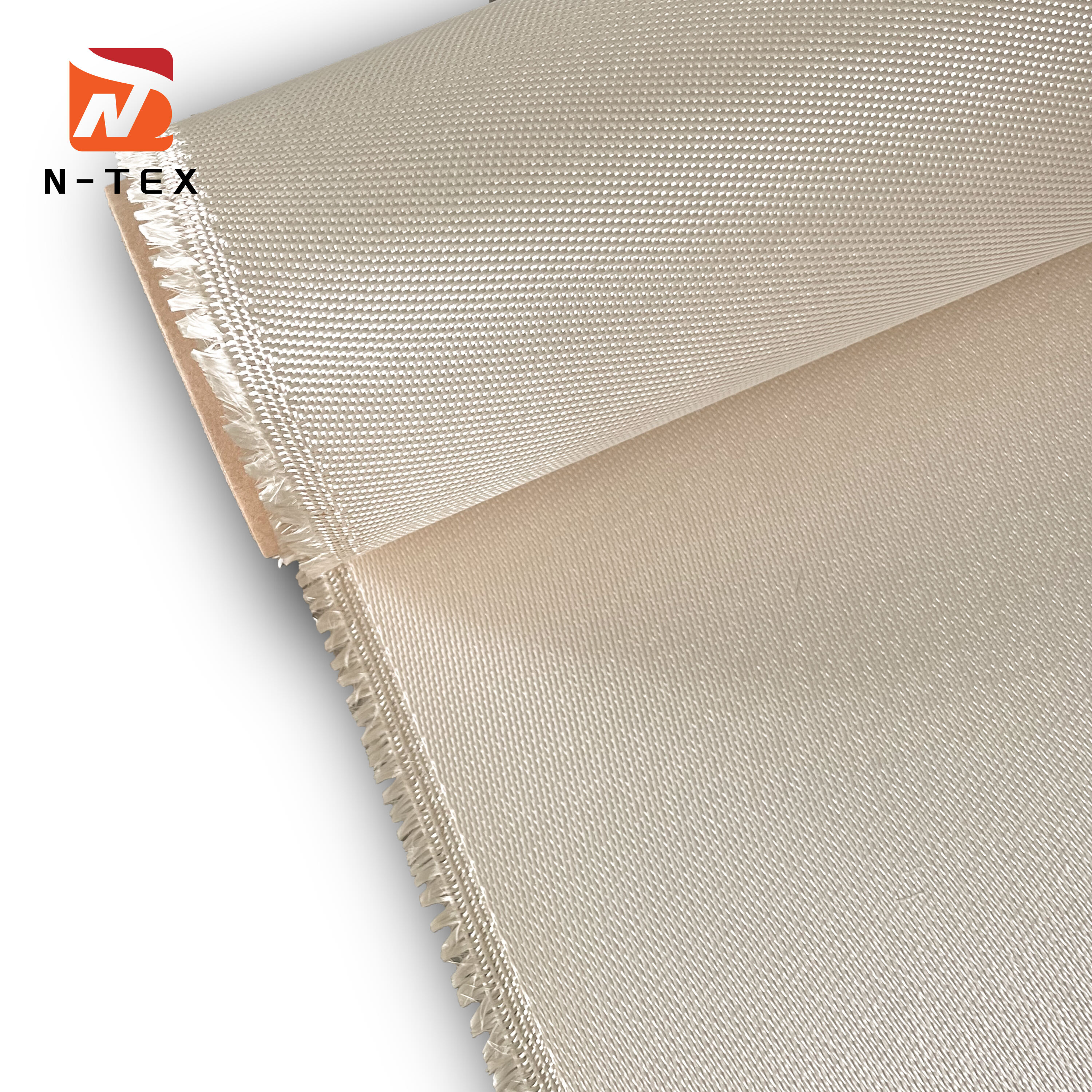

Nanjing Xinwei High Temperature Material Co Ltd is a reputable producer of high-silica fabrics covers a space of the size of 20 000 square meters There are high silica fabric in the factory Our production capacity can reach the 200 000 meter mark per month and our inventory is adequate to ensure that the first shipment is delivered We also have customers from all over the world and we are willing to provide top quality service to every customer

We are very strict about the quality of our products as we believe that the product is the heart and soul of any business. Every item we send has been checked for quality. We are able to accurately measure the thickness and gram weight of every product, and high silica fabric the products for hue differences to prevent after-sales problems.

Our company manufactures mainly silica mats and super mats. The products we high silica fabric can be tailored to meet the needs of the customer. different colors and coatings, to meet customer needs, and also provide good service. We also have various sizes of fire-blankets which can be used in high-temperature applications, fire safety, and other areas.

Our inventory is kept in a safe high silica fabric so that we are able to deliver the product to the customer as soon as they need it. The annual volume of our products could reach 5 million meters. The delivery time of ordinary products is generally about 10-15 days, the delivery speed is fast, for more than 3000 customers across the globe, we export to more than 20 countries in the world.